Flexible Materials & Films

Rely on a team with more than 60 years of printing experience working with synthetics, durables and plastics like flexible PVC and specialty films.

Trust the Materials Experts

Visual Marking Systems has decades of experience converting almost every type of durable material for equipment decals, labels, nameplates, overlays and fleet graphics. With deep expertise in synthetics, plastics and specialty films, we’ll help you select the right substrate for your application, environment and performance needs.

Durable materials must be matched to the proper printing technology, life expectancy and environmental conditions. Many synthetics also require specific coatings or pre-treatments to ensure proper ink adhesion and curing.

As an industry-leading converter, VMS offers broad material capabilities, advanced production techniques and a wide range of converting services under one roof. Our processes are supported by ISO 9001 quality systems, Kanban inventory solutions and a commitment to consistent, high-performance results.

Material & Film Types

Below is an overview of the most commonly used flexible materials for UV screen, UV digital and latex printing.

Polycarbonate Material

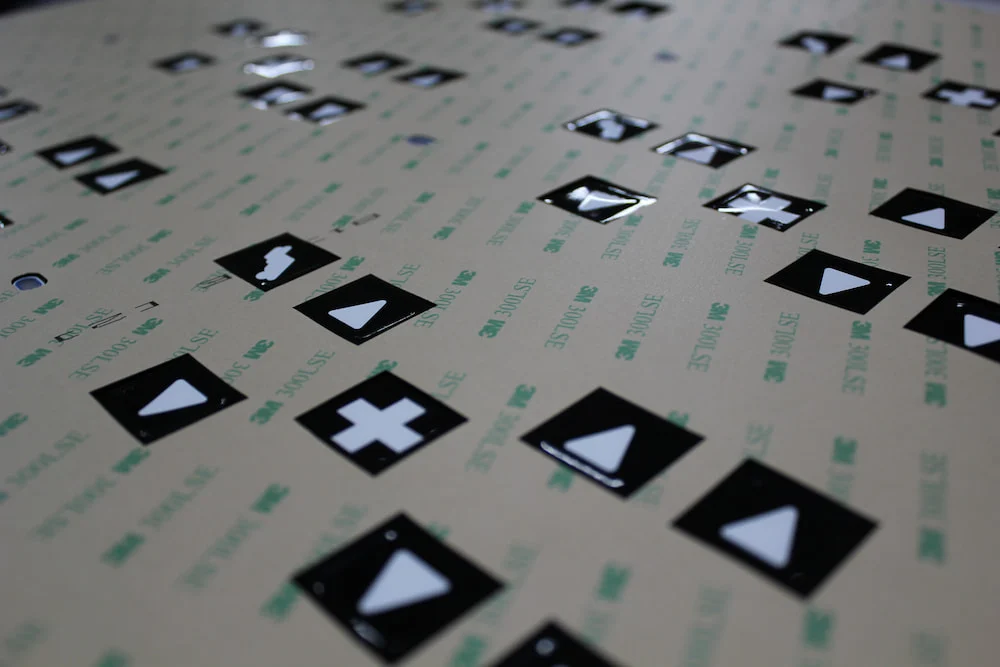

Polycarbonate is a tough, dimensionally stable film used for high-performance graphic applications where impact strength and clarity are essential. Its excellent resistance to heat, chemicals and abrasion makes it ideal for control panels, graphic nameplates and overlays, labels and polycarbonate decals that require long-term durability. Polycarbonate can be finished with smooth or textured surfaces and is easily die-cut, embossed or selectively printed. It can also be thermoformed to fit complex equipment housings, control panels and unique product shapes.

Polyester Material

Polyester (PET) is a strong, non-conforming film known for excellent tear resistance, temperature stability and optical clarity. It is widely used in applications that require rigidity and long-term performance, such as appliance panels, keypad overlays, membrane switches, security labels and high-end facestock. Polyester comes in clear, white, metalized and specialty finishes, and holds up extremely well to solvents, cleaning agents and heavy use.

PVC Material (Vinyl)

Flexible PVC (vinyl) is one of the most versatile materials available for graphics. It conforms easily to curved or uneven surfaces, making it ideal for decals, equipment labels, safety markings, warning labels and long-term outdoor graphics. PVC is available in flexible, semi-rigid and rigid grades depending on the formulation. It accepts ink well, resists outdoor elements and offers a wide range of finishes including matte, gloss, textured or transparent.

Adhesives

The right adhesive determines how well a graphic performs over time. Options vary based on surface type, texture, temperature range and expected environmental exposure. VMS offers permanent, removable, repositionable and high-tack adhesives that adhere to plastics, metals, powder-coated surfaces, low-surface-energy materials, vehicles and more. Proper adhesive selection ensures long-term bonding strength, clean removability when needed and consistent performance in both indoor and outdoor conditions.

Overlaminate

Overlaminate, also known as overlam, provides a protective layer that shields graphics from UV exposure, fading, abrasion and chemicals. It is used to extend the life of decals, labels, wraps and equipment panels that undergo heavy wear or harsh environments. Available in gloss, matte and textured finishes, overlaminate adds rigidity and durability to the printed film and is ideal for long-term fleet graphics, outdoor signage and industrial overlays.

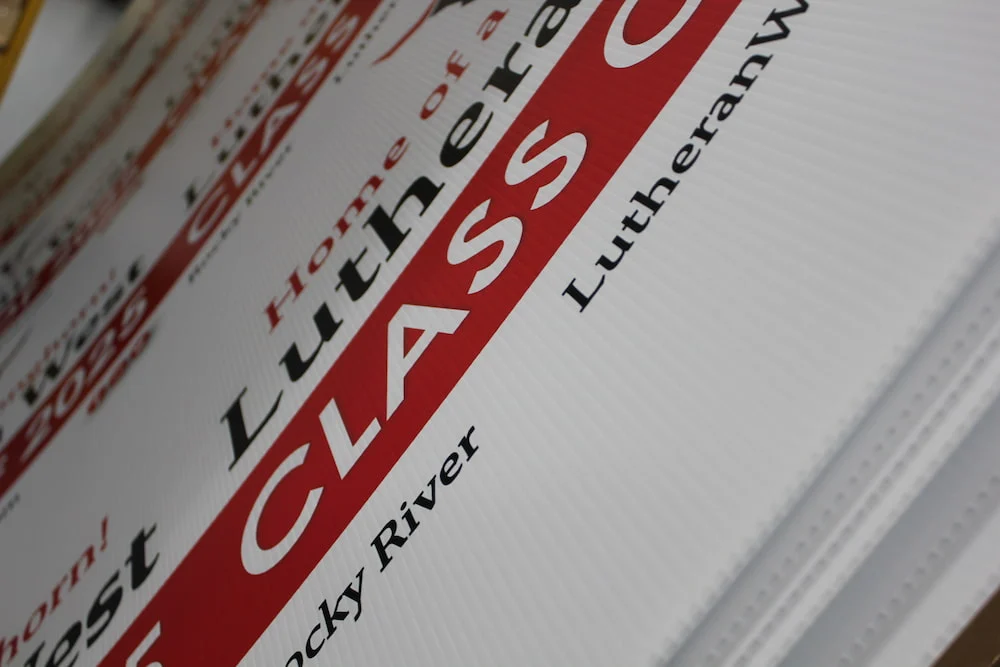

Fluted Polypropylene Sheet

Fluted polypropylene is a lightweight corrugated material that offers excellent rigidity and durability for its weight. It resists water, chemicals and stains, making it ideal for indoor and outdoor signage, point-of-purchase displays, reusable packaging and event graphics. Twin-wall construction provides structure while remaining economical for short- to mid-term applications.

Perforated Window Vinyl

Perforated window vinyl (window perf) allows full-color graphics on the outside while maintaining visibility from the inside. It is commonly used for vehicle wraps, storefronts and bus advertising. The small perforations let light pass through, preventing the window from feeling opaque while still delivering a high-impact graphic. Window perf also reduces glare and adds a layer of privacy without blocking outward visibility.

Polypropylene Material

Polypropylene is a durable yet economical synthetic substrate ideal for short-term indoor and limited outdoor use. It is tear-resistant, moisture-resistant and holds vibrant print quality. Because it is cost-effective, polypropylene is widely used for retail signage, displays, shelf danglers, temporary decals and UL-recognized label applications. It offers a cleaner, smoother finish than paper without the cost of vinyl or polyester.

Wrap Vinyl for Vehicles

Vehicle wrap vinyl is engineered specifically to stretch, conform and maintain adhesion on complex vehicle surfaces. Premium wrap films from partners like 3M, Avery Dennison and Arlon deliver strong color vibrancy, long outdoor life and clean removal. Wrap vinyl hides minor surface imperfections, molds around contours and is available in cast or calendared grades. Options include printable vinyl for custom wraps, pre-colored vinyl for solid designs, reflective films for emergency vehicles, non-PVC vinyl for sustainable programs and marine-grade vinyl for boats.

Strengthen Your Brand Today

Enhance your brand with high-quality materials chosen specifically for your application needs. VMS helps guide your material selection to ensure performance, durability and cost efficiency.