When designing labels, decals, or overlays for your product identification on your industrial equipment, selecting the adhesive is as important a component as the base material. The following will help you learn about the differences in decal adhesives, the applications they support, and the questions your OEM labels and decals supplier should ask about your application.

|

|

|

|

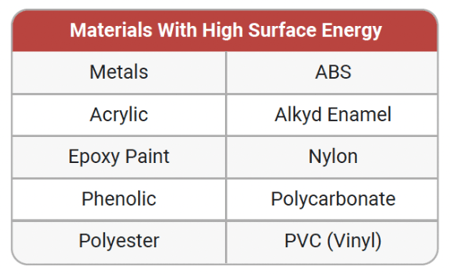

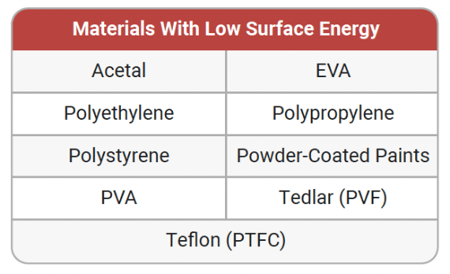

The surface energy of the material a decal is applied to plays a major role in choosing the proper adhesive. Adhesion is the molecular force of attraction between unlike materials; surface energy is the strength of attraction between surface and adhesive. The higher the surface energy, the greater the molecular attraction. The lower the surface energy, the weaker the attractive forces. Surface energy is measured by dynes per centimeter. The dyne level is the actual reading of the critical surface tension.

Permanent adhesives: Permanent adhesives tend to continue to increase in bond strength with time, usually reaching ultimate adhesion in 72 hours to one week after application.

Removable adhesives: Removable adhesives reach ultimate adhesion in one to 24 hours after application. Their bond strength remains low for up to two years depending on the product. After this period, the adhesive will stiffen and become permanent. Although termed “removable” from most smooth surfaces, these adhesives may not be completely removable from some matte or textured surfaces. Testing their removability from painted surfaces is strongly recommended. Most suppliers carry removable adhesives on vinyl.

Repositionable adhesives: These pressure-activated adhesives have a low initial tack but high ultimate adhesion. They can be lifted and reapplied to a substrate during installation without stretching the film. During application, a squeegee is used to activate the adhesive. After 24 to 72 hours, adhesion builds and the film will be damaged if removal is attempted. This type of adhesive is excellent for fleet markings and in other applications where position is critical.